SINGLE SHAFT SHREDDER

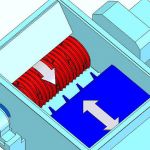

Single shaft shredders feature a solid steel rotor with multi-edge tool steel cutters and stationary bed knives. These hopper fed, single shaft grinders, incorporate sizing screens to provide a uniform finished piece size.

Types

-

Single Shaft Shredder

Stand-alone single shaft shredders for resin-based materials and wood cutoffs

-

Auger-Pak™ – Single Shaft Shredder Systems

Shredding systems for the separation of metal from wood waste to create a finished wood product

SINGLE SHAFT SHREDDER

Piranha Series

We call our single shaft shredders “Piranhas” because of their voracious appetite, and small piece-sizing. The Komar Piranha is designed for the reclamation and reduction of a variety of products including processed plastics, paper, wood, trim stock, vinyl, and leather.

- Features:

-

- Medium Speed / High Torque Design

- Rigid Precision Machined Frame

- Solid Cutting Shaft

- Indexable Cutting Inserts

- Fluid Coupling, Hydraulic Ram

AUGER – SHREDDER SYSTEMS

Making mulch and boiler fuel

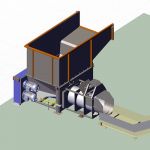

When customers want to make mulch or boiler fuel from their industrial wood waste, Komar suggests an Auger-Shredder system. The Komar Auger-Pak™ provides an excellent method to precrush the wood, optimizing the shredding process of the Komar Piranha single shaft shredder. Since the Auger-Pak™ is designed to crunch through the dense material with ease, it plays an important role in extending the life of the single shaft shredder.

Wood Waste with Nails

This system is designed to process industrial wood waste into mulch or boiler fuel.

Step 1 – Primary Reduction: The Komar EM-60W Auger-Pak™, with compression end gate, efficiently pre crushes the wood waste.

Step 2 – Secondary Reduction: The wood waste is fed directly into a single shaft shredder for finished piece sizing.

Step 3 – Nail Removal: A magnet is used to separate the nails from the finished wood product.

Technology: Auger-Pak™ EM-60W, Single Shaft Shredder

Auxiliary Equipment: Compression end gate

Wood Waste with Bolts

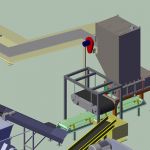

The system is designed to process industrial wood waste, containing larger metal brackets and bolts, into mulch or boiler fuel.

Step 1 – Primary Reduction: Occurs at the EMD-80W dual Auger-Pak™, with a compression end gate.

Step 2 – Metal Liberation: A dual shaft shredder then liberates the metal bolts and brackets. A magnet pulls the liberated metal out.

Step 3 – Secondary Reduction: The wood travels along a conveyor into a single shaft shredder for finished piece sizing.

Step 4 – Nail Removal: Another magnet pulls the remaining nails out of the finished wood product.

Technology: Auger-Pak™ EMD-80W, Two Shaft Shredder, Piranha Single Shaft Shredder

Auxiliary Equipment: Hydraulic compression end gate, steel hinge conveyor, troughing conveyor, 2 cross belt magnets, 2 incline conveyors, air delivery system