Industrial Wood Waste Processing Solutions

Whether a shipping facility, a furniture company, or an industrial manufacturing site, all types of businesses produce wood waste. Often that waste is comprised of unneeded pallets, skids, crates, spools, and/or manufacturing scrap. Without proper management techniques, this scrap will quickly overtake the facility and drastically inflate hauling costs.

Whether a shipping facility, a furniture company, or an industrial manufacturing site, all types of businesses produce wood waste. Often that waste is comprised of unneeded pallets, skids, crates, spools, and/or manufacturing scrap. Without proper management techniques, this scrap will quickly overtake the facility and drastically inflate hauling costs.

The Komar Advantage

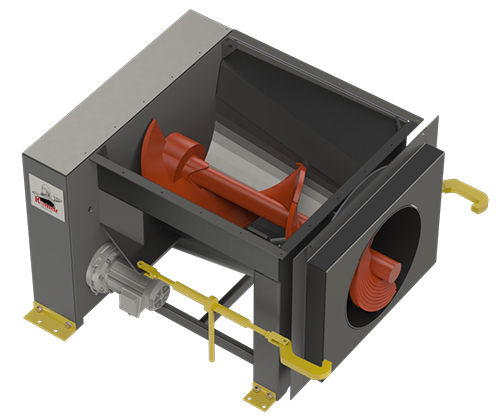

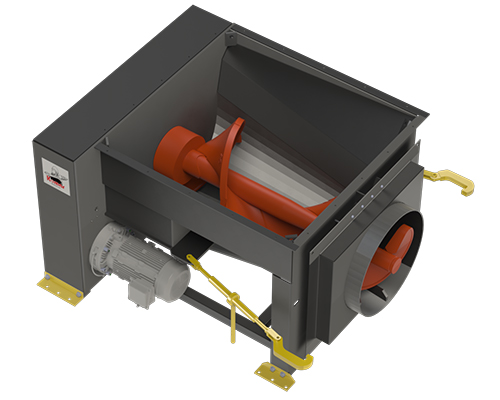

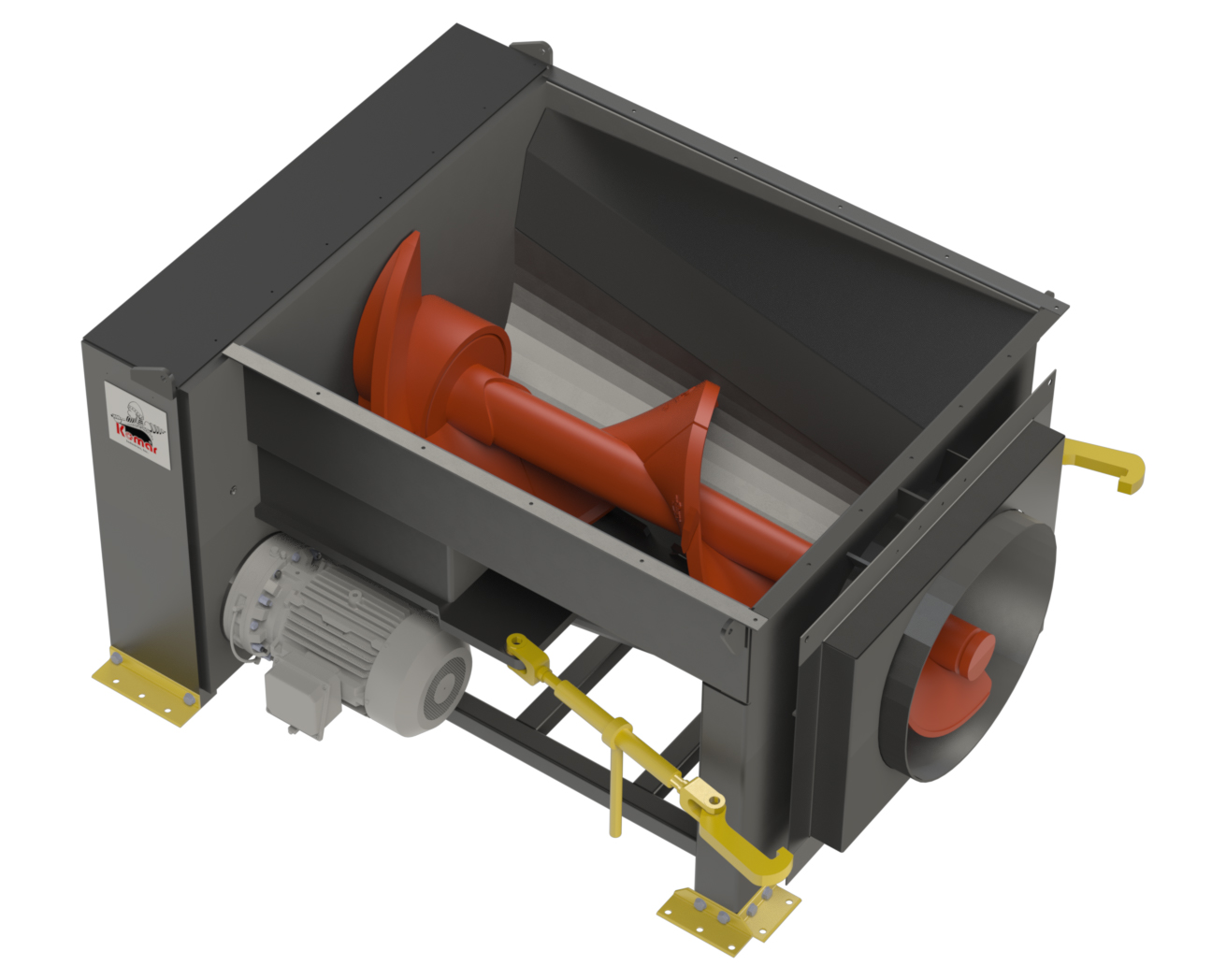

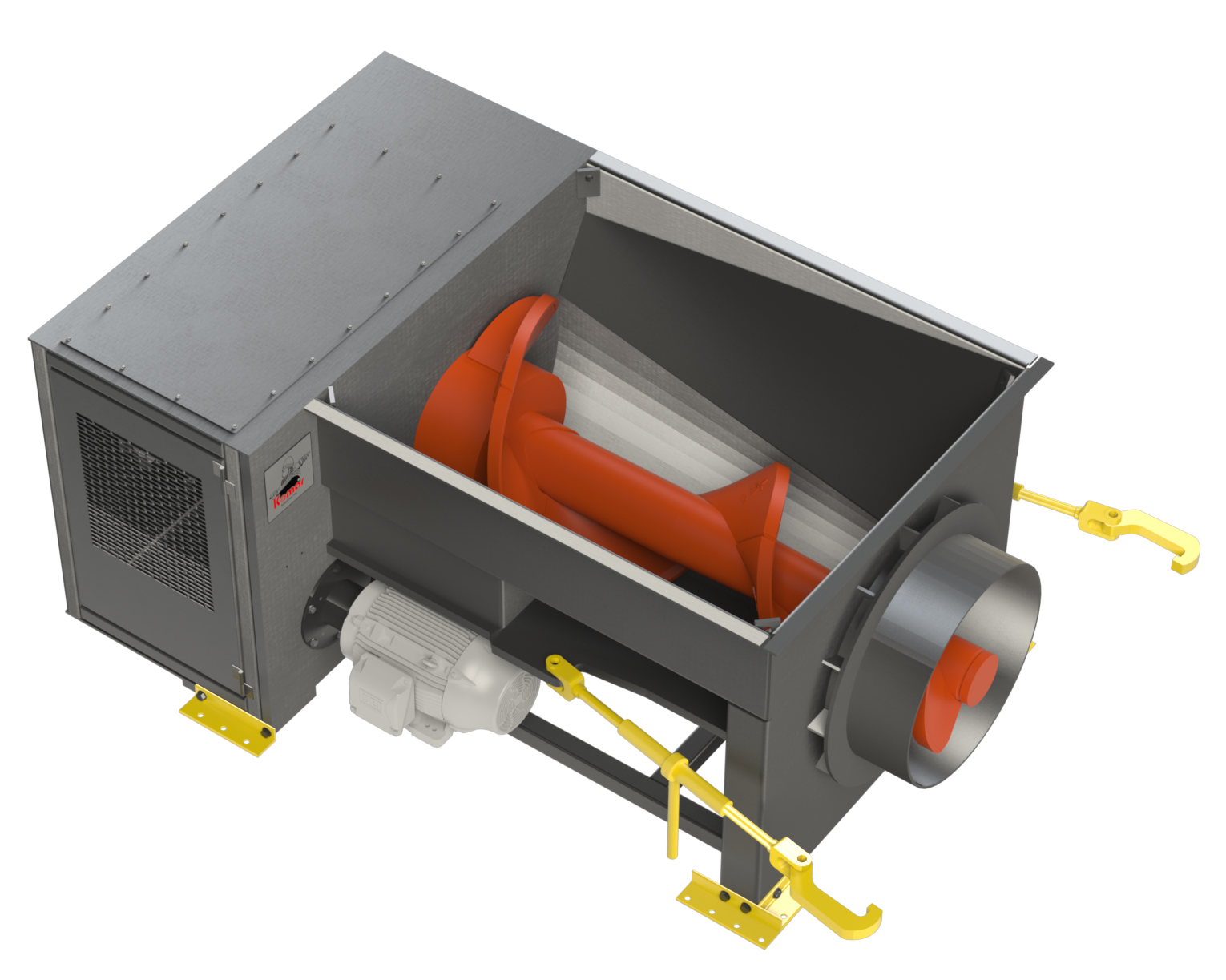

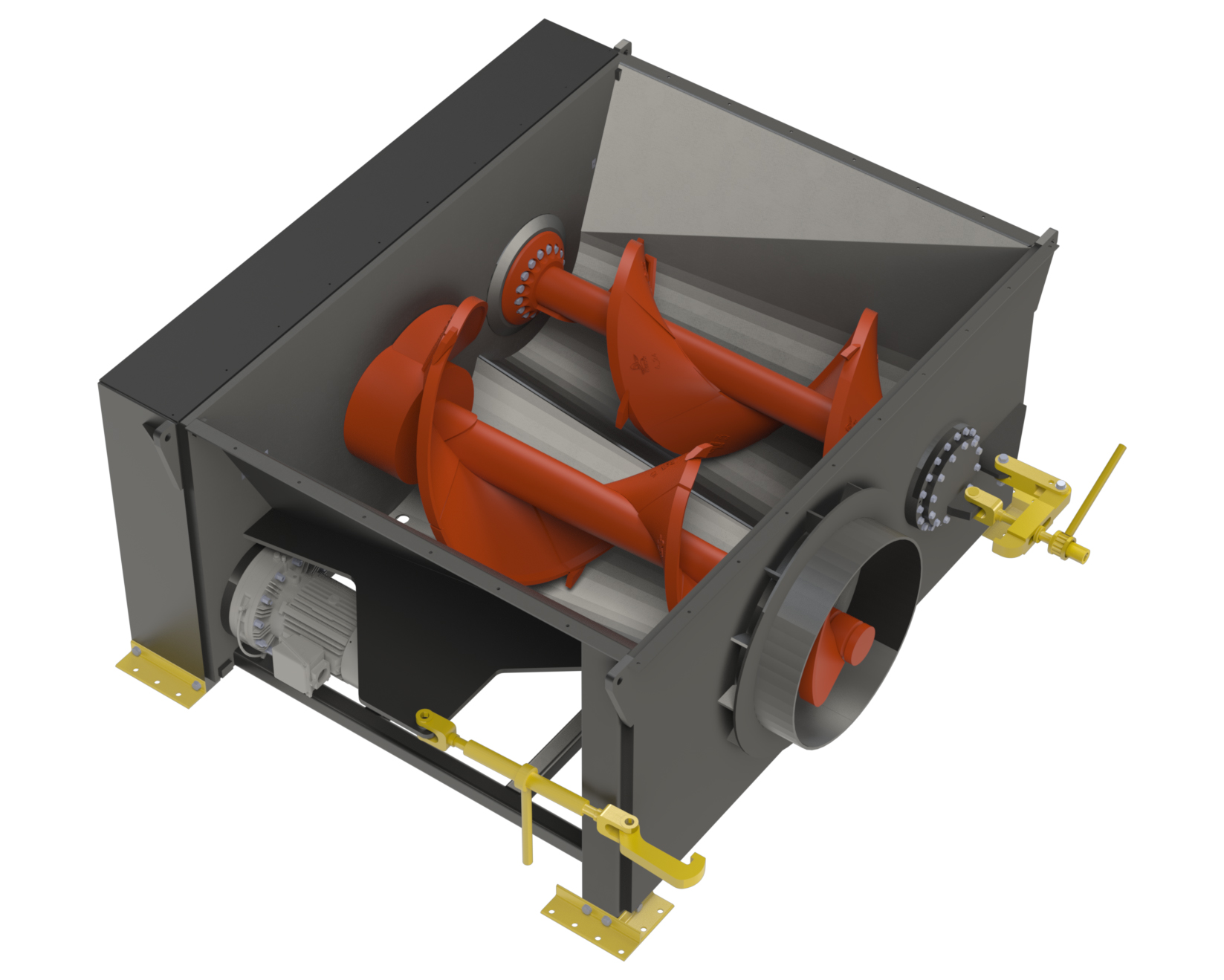

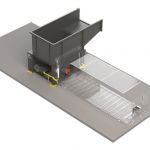

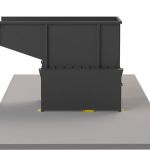

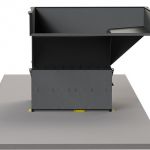

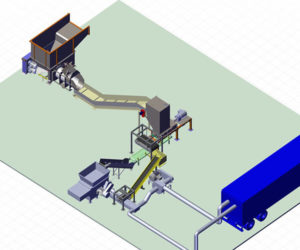

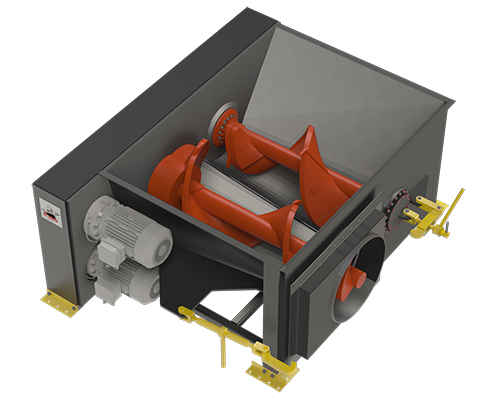

Komar Industries can help you get a handle on wood waste. We manufacture the safest, most cost-effective, and most efficient industrial wood waste processing solution on the market – the Komar Auger-Pak®. Coming in a wide array of sizes and configurations, this auger compactor series shreds and compacts in one machine, completely automating material breakdown, while delivering a staggering 5:1 volume reduction.

What is the secret to making the best auger compactors for wood waste?

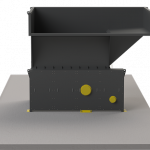

Komar’s wood processors uniquely feature auger screws that are made of solid-alloy steel shafts and cast steel flighting. This high-quality durable construction, along with a drive system that boasts a 500% shock load rating, ensures that our augers crunch through large loads with ease, year after year. In addition, our triple patented bearing support system allows us to house the largest most powerful auger screws in the industry.

What are the biggest benefits of the Komar solution?

- Quickly Rids Yard and Facility of Wood Waste

- Substantially Reduces Transportation Costs

- Wood Shredding and Compaction in One Machine

- Eliminates Need for Dangerous Manual Breakdown

- Safely Handles Tramp Metal such as Nails and Bolts

- Easy-To-Use Controls

- Low Noise and Dust

How do we select the right model and configuration for you?

The perfect wood processing solution depends on many factors, such as the size, type, and volume of wooden consumables. We also consider where you would like to locate your equipment, and which feeding method best fits your operations. With decades of experience, the experts at Komar Industries can help select the best auger-compactor for your needs.

Contact us for additional information.

– Dave McCarl, Facilities Supervisor, Traco

Komar Auger-Pak® Industrial Wood Models

To fit for your job, we offer a broad range of both Single and Dual Auger-Paks®.

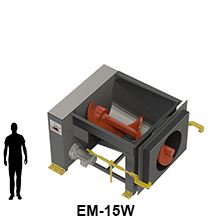

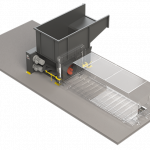

EM-15W Pallet Shredder

| Processing Specifications | |

| Horsepower | 15 |

| Peak Tons per Hour | 2 |

| Standard Pallets per Charge | 2 |

| Largest Pallet | 42″ x 48″ |

| Largest Crate | 36″ x 36″ x 60″ |

| Largest Spool | 36″ |

| Physical Specifications | |

| Footprint (L x W x H) | 89.6″ x 72″ x 60.2″ |

| Chamber Size (L x W) | 60″ x 59.25″ |

| Weight (lbs)* | 10,625 |

| rpm | 7.42 |

| torque (ft-lbs) | 10,624 |

EM-40W Pallet Shredder

| Processing Specifications | |

| Horsepower | 40 |

| Peak Tons per Hour | 5 |

| Standard Pallets per Charge | 10 |

| Largest Pallet | 48″ x 96″ |

| Largest Crate | 48″ x 48″ x 48″ |

| Largest Spool | 48″ |

| Physical Specifications | |

| Footprint (L x W x H) | 115.75″ x 91.75″ x 68.5″ |

| Chamber Size (L x W) | 80″ x 75.25″ |

| Weight (lbs)* | 19,235 |

| rpm | 7.42 |

| torque (ft-lbs) | 28,331 |

Site: Cranberry Township, PA

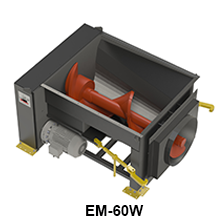

EM-60W Pallet Shredder

| Processing Specifications | |

| Horsepower | 60 |

| Peak Tons per Hour | 8 |

| Standard Pallets per Charge | 12 |

| Largest Pallet | 60″ x 96″ |

| Largest Crate | 48″ x 48″ x 60″ |

| Largest Spool | 60″ |

| Physical Specifications | |

| Footprint (L x W x H) | 128.25″ x 92″ x 65.5″ |

| Chamber Size (L x W) | 92″ x 75.25″ |

| Weight (lbs)* | 24,358 |

| rpm | 10.17 |

| torque (ft-lbs) | 30,972 |

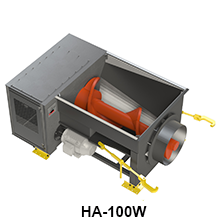

HA-100W Pallet Shredder

| Processing Specifications | |

| Horsepower | 100 |

| Peak Tons per Hour | 10 |

| Standard Pallets per Charge | 12 |

| Largest Pallet | 60″ x 96″ |

| Largest Crate | 48″ x 48″ x 60″ |

| Largest Spool | 60″ |

| Physical Specifications | |

| Footprint (L x W x H) | 157″ x 106.25″ x 68.5″ |

| Chamber Size (L x W) | 90″ x 75″ |

| Weight (lbs)* | 25,000 |

| rpm | 15.7 |

| torque (ft-lbs) | 50,390 |

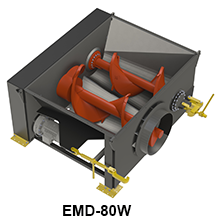

EMD-80W Pallet Shredder

| Processing Specifications | |

| Horsepower | 80 |

| Peak Tons per Hour | 5-10 |

| Standard Pallets per Charge | 20 |

| Largest Pallet | 84″ x 144″ |

| Largest Crate | 84″ x 84″ x 144″ |

| Largest Spool | 96″ |

| Physical Specifications | |

| Footprint (L x W x H) | 125.6″ x 138.4″ x 69.5″ |

| Chamber Size (L x W) | 92″ x 123.25″ |

| Weight (lbs)* | 36,453 |

| rpm of Primary Compaction Auger | 10.17 |

| torque (ft-lbs) | 30,972 |

EMD-180W Pallet Shredder

| Processing Specifications | |

| Horsepower | 180 |

| Peak Tons per Hour | 10-20 |

| Standard Pallets per Charge | 20 |

| Largest Pallet | 84″ x 144″ |

| Largest Crate | 84″ x 84″ x 144″ |

| Largest Spool | 96″ |

| Physical Specifications | |

| Footprint (L x W x H) | 165.5″ x 127″ x 96″ |

| Chamber Size (L x W) | 92″ x 123.25″ |

| Weight (lbs)* | 44,453 |

| rpm of Primary Compaction Auger | 20.35 |

| torque (ft-lbs) | 30,972 |

Making Mulch or Boiler Fuel

The bulk reduction provided by the Komar Auger-Pak™ drastically reduces hauling costs, giving the majority of our customers the largest cost savings. Some of our customers, however, desire to make their wood waste into mulch or boiler fuel. To meet this objective, Komar suggests one of the three solutions below, depending upon your wood waste’s metal content.