Komar Strengthens Its North American Platform With the Acquisition of Metro Compactor Service

Learn More →Komar Strengthens Its North American Platform With the Acquisition of Metro Compactor Service

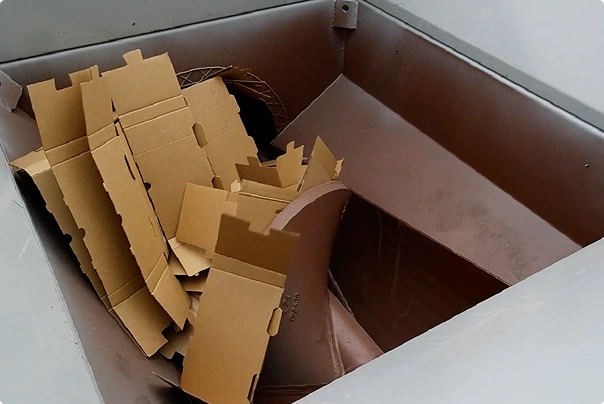

Learn More →Cardboard, pallets, and loose general waste take up valuable space, tie up labor, and reduce operational efficiency. Komar single-screw augers are designed for one purpose: reliably processing materials so your team can focus on value-added work while maximizing tons per haul.

Designed for industrial-grade challenges. Made with heavy-duty materials for long-term performance you can count on.

Direct waste from elevated drop points into the hopper

Guide material into the processing chamber

Automated lifting and dumping of collection containers into the auger

Automate and control material flow with integrated infeed or discharge conveyor systems

Optional dust curtains and exhaust fans added to enclosed hopper to keep dust out of your facility

Integrated lighting for clear visibility inside enclosed hoppers

Remote monitoring, performance data, and service diagnostics (Subscription required)

208V/3ph, 230V/3ph, 575V/3ph

Not all options are available with every model.

“Our facility is a 110,000-square-foot operations center for Goodwill of Southwestern Pennsylvania. We get between 1.2 to 1.5 million pounds of material a day, and tonnage increases significantly during the summer. The Komar auger has increased daily soft trash, wood pallets, and general trash efficiency by 30% and 40% with furniture. I love to give shock-and-awe tours to show off the Komar Auger, which compacts 8.5 to 9 tons into each payload.”

Bob Kagle, Director of Retail Logistics, Goodwill of Southwestern Pennsylvania

“Since installing our Komar Auger, we have improved our operations tremendously. The auger units have reduced labor from six people down to one person, who oversees the conveyor lines and compactors. We have gone from a 2-ton payload to a 10-ton-plus payload, per 40-yard container, reducing our annual pull charges by over 75%. We have less downtime and have eliminated jams due to the slow operation of the old compactors. Best of all, we had less than a one-year return on investment.”

John Hefty, Operations Manager, GameStop

“We estimate that the Komar Auger has saved us 1,300 hours of labor per year, has reduced our hauling cost by two-thirds, and has given La-Z-Boy a safer process and more floor space.”

Troy Kvingedal, Facilities Supervisor, La-Z-Boy

“Our disposal costs have dropped, which at least covers the cost of the compactors. Aside from the monetary aspect, the compactors allow the stores to be considerably cleaner. Cleanup at night is much easier because we have no trash cluttering up the back room of the store. All in all, we are very pleased with the compactors.”

Doug Gehrig, CEO, McDonald’s of Southwest Louisiana

Every waste-handling system has its purpose. The key is understanding which compactor type aligns with your material volume, waste characteristics, and operational layout. Komar Industries helps organizations make informed decisions rooted in long-term clarity, not short-term urgency.

Our solutions are tailored to meet the unique needs of a wide range of industries, including:

| Single Screw Augers |  AC-15S |  AS-15G |  AC-20S |  AS-20G |  AS-40G |  AS-60G |

|---|---|---|---|---|---|---|

| Horsepower | 15 | 15 | 20 | 20 | 40 | 60 |

| Drive Type | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical |

| Power Requirement | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz |

| Overcurrent Protection | 50 amp | 50 amp | 50 amp | 50 amp | 125 amp | 175 amp |

| Auger Speed | 8.4 RPM | 7.4 RPM | 8.8 RPM | 6.0 RPM | 7.4 RPM | 10.2 RPM |

| Torque | 9,300 ft-lbs | 10,600 ft-lbs | 11,900 ft-lbs | 17,600 ft-lbs | 28,300 ft-lbs | 30,950 ft-lbs |

| Auger Type | Straight | Tapered | Straight | Tapered | Tapered | Tapered |

| Auger Diameter | 28″ | 39.5″ to 25″ | 28″ | 46.75″ to 28.375″ | 50″ to 28.375″ | 39.5″ to 25″ |

| Displacement Rate | 1 ton/hr | 1 ton/hr | 4 ton/hr | 4 tons/hr | 3–6 ton/hr | 6.4 tons/hr |

| Container Fill (40 yd) | 4–8 tons | 4–8 tons | 4–8 tons | 4–8 tons | 6–10 tons | Up to legal road limit |

| Chamber Opening | 51″ × 67.5″ | 60″ × 59″.25 | 78.5″ × 76.25″ | 70″ × 69″ | 80″ × 75.25″ | 90″ × 72.25″ |

| Full System Weight (Includes Hopper) | 4,200 lbs | 10,625 lbs | 12,000 lbs | 15,275 lbs | 19,100 lbs | 24,250 lbs |

| Feed Methods | Hand, Forklift, Tipper | Hand, Forklift, Tippers, Conveyors, Chute | Hand, Forklift, Tipper | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute |

| Cardboard Single Screw Augers |

AS-15G

AS-15G |

AS-20G

AS-20G |

AS-40G-HS

AS-40G-HS |

AS-60G

AS-60G |

|---|---|---|---|---|

| Horsepower | 15 | 20 | 40 | 60 |

| Drive Type | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical |

| Power Requirement | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz |

| Overcurrent Protection | 50 amp | 50 amp | 125 amp | 175 amp |

| Auger Speed | 7.4 RPM | 6.0 RPM | 14.8 RPM | 10.2 RPM |

| Torque | 10,600 ft-lbs | 17,600 ft-lbs | 14,150 ft-lbs | 30,950 ft-lbs |

| Auger Type | Tapered | Tapered | Tapered | Tapered |

| Auger Diameter | 39.5″ to 25″ | 46.75″ to 28.375″ | 50″ to 28.375″ | 39.5″ to 25″ |

| Displacement Rate | 1 ton/hr | 2.5 ton/hr | 6–12 ton/hr | 3.5 ton/hr |

| Container Fill (40 Yd) | 4–8 tons | 4–8 tons | 6–10 tons | Up to legal road limit |

| Chamber Opening (L×W) | 60″ × 59.25″ | 70″ × 69″ | 80″ × 75.25″ | 90″ × 72.25″ |

| Full System Weight (Includes Hopper) | 10,625 lbs | 15,275 lbs | 18,825 lbs | 24,250 lbs |

| Feed Methods | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute |

| Wood Single Screw Augers |  AS-15W |  AS-40W |  AS-60W |

|---|---|---|---|

| Horsepower | 15 | 40 | 60 |

| Drive Type | Electro-Mechanical | Electro-Mechanical | Electro-Mechanical |

| Power Requirement | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz | 480 V, 3 PH, 60 Hz |

| Overcurrent Protection | 50 amp | 125 amp | 175 amp |

| Auger Speed | 7.4 RPM | 7.4 RPM | 10.2 RPM |

| Torque | 10,600 ft-lbs | 28,300 ft-lbs | 31,000 ft-lbs |

| Auger Type | Tapered with Teeth | Tapered with Teeth | Tapered with Teeth |

| Auger Diameter | 39.5” to 25” | 50” to 28.375” | 52.75” to 28.375” |

| Displacement Rate | 2 ton/hr | 5 ton/hr | 8 ton/hr |

| Standard Pallets/Charge | 2 | 8 | 12 |

| Pallets/Hr (continuous, even feed) | 60 | 100 | 125 |

| Pallet Size (LxW) – Standard | 42”× 48” | 72” × 48” | 84” × 48” |

| Pallet Size (LxW) – Special Configuration & Handling Required | 72” × 48” | 120” × 60” | 120” × 60” |

| Crate Size (L×W×H) – Standard | 36” × 36” × 36” | 48” × 48” × 48” | 60” × 48” × 48” |

| Crate Size (LxWxH) – Special Configuration & Handling Required | 36” × 36” × 36” | 84” × 48” × 48” | 84” × 48” × 48” |

| Spool Size (dia.) – Standard | 36” | 48” | 60” |

| Spool Size (dia.) – Special Configuration & Handling Required | 36” | 60” | 60” |

| Occasional Piece Length (special configuration & handling required) | Up to 60” | Up to 120” | Up to 120” |

| Container Fill (40 Yd) | 4–6 tons | 6–10 tons | 6 tons |

| Chamber Opening (LxW) | 60” × 59.25” | 80” × 75.25” | 90” × 75.25” |

| Full System Weight (Includes Hopper) | 10,625 lbs | 19,200 lbs | 24,350 lbs |

| Feed Methods | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute | Hand, Forklift, Tipper, Conveyor, Chute |

| Feed Materials | Wood – Pallets, Crates, Spools | Wood – Pallets, Crates, Spools | Wood – Pallets, Crates, Spools |

Factors such as waste volume, material type, operational speed, and output requirements need to be considered when making a selection. Our product experts are here to help you pick the right solution for your needs.

Thanks to precision machining, sealed bearings, and an automatic lubrication system, routine maintenance is minimal and focused on inspection rather than frequent service. Komar also offers Preventative Maintenance programs to help keep equipment operating reliably over the long term.

Yes—conveyors, tippers, and chute feeding systems work with all Komar augers.

Hoppers are available in three styles. Knowing which is best suited for your facility depends on where the equipment is located and how it’s being fed. Covered hoppers are designed for manual loading in outdoor settings. The open-top configuration supports top loading, and the plug-in hopper style is designed for dock integration.

Auger systems typical payback is within 24 months on average, though some facilities hit a positive return in as little as a year.

Cardboard, general/municipal solid waste (MSW), wood pallets, crates, and spools, and can all be processed.

Yes. Many Komar augers are designed to process continuous material flow when paired with metered conveyors.

We are a waste solutions company. With a wide array of application-specific models and advanced engineering capabilities, we look forward to guiding you to the best solution for the job.

Schedule a free waste stream evaluation to identify the right equipment and processes for your space, waste types, and volume.

Every waste-handling system has its purpose. The key is understanding which compactor type aligns with your material volume, waste characteristics, and operational layout. Komar Industries helps organizations make informed decisions rooted in long-term clarity, not short-term urgency.

Auger Compactors

Ideal for:

Augers excel where speed, reliability, and material destruction are critical.

Vertical Compactors

Ideal for:

Vertical units are compact, simple, and cost-effective for everyday waste streams.

Stationary Compactors

Ideal for:

These systems anchor permanently to a site, allowing large containers to be swapped as needed.

Self-Contained Compactors

Ideal for:

The integrated design prevents contamination and simplifies transport.

Choosing the Wisest Path Forward

The right system depends on:

By evaluating the nature of the waste stream first, facilities can choose the compactor that brings the greatest long-term value, safety, and operational clarity.