Komar Dual Auger-Pak®

EMD WOOD SERIES

- Most cost-effective solution for processing oversized wood waste

- Substantially reduces transportation costs oversized wood waste

- Shreds and compacts in one machine

- Eliminates the need for dangerous manual breakdown

- Safely handles tramp metal such as nails and bolts

- Low noise and dust

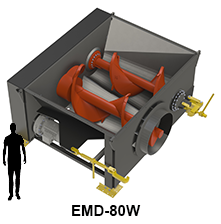

EMD-80W

| EMD-80W Processing Specifications | |

| Horsepower | 80 |

| Tons / Hr | 5-10 |

| Standard Pallets / Charge | 20 |

| Largest Pallet | 84″ x 144″ |

| Largest Crate | 84″ x 84″ x 144″ |

| Largest Spool | 96″ |

| EMD-80W Physical Specifications | |

| Footprint (L x W x H) | 125.6″ x 138.4″ x 69.5″ |

| Chamber Size (L x W) | 92″ x 123.25″ |

| Weight (lbs)* | 36,453 |

| rpm of Primary Auger | 10.17 |

| torque (ft-lbs) | 30,972 |

EMD-180W

| EMD-180W Processing Specifications | |

| Horsepower | 180 |

| Tons / Hr | 10-20 |

| Standard Pallets / Charge | 20 |

| Largest Pallet | 84″ x 144″ |

| Largest Crate | 84″ x 84″ x 144″ |

| Largest Spool | 96″ |

| EMD-180W Physical Specifications | |

| Footprint (L x W x H) | 165.5″ x 127″ x 96″ |

| Chamber Size (L x W) | 92″ x 123.25″ |

| Weight (lbs)* | 44,453 |

| rpm of Primary Auger | 20.35 |

| torque (ft-lbs) | 30,972 |

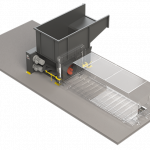

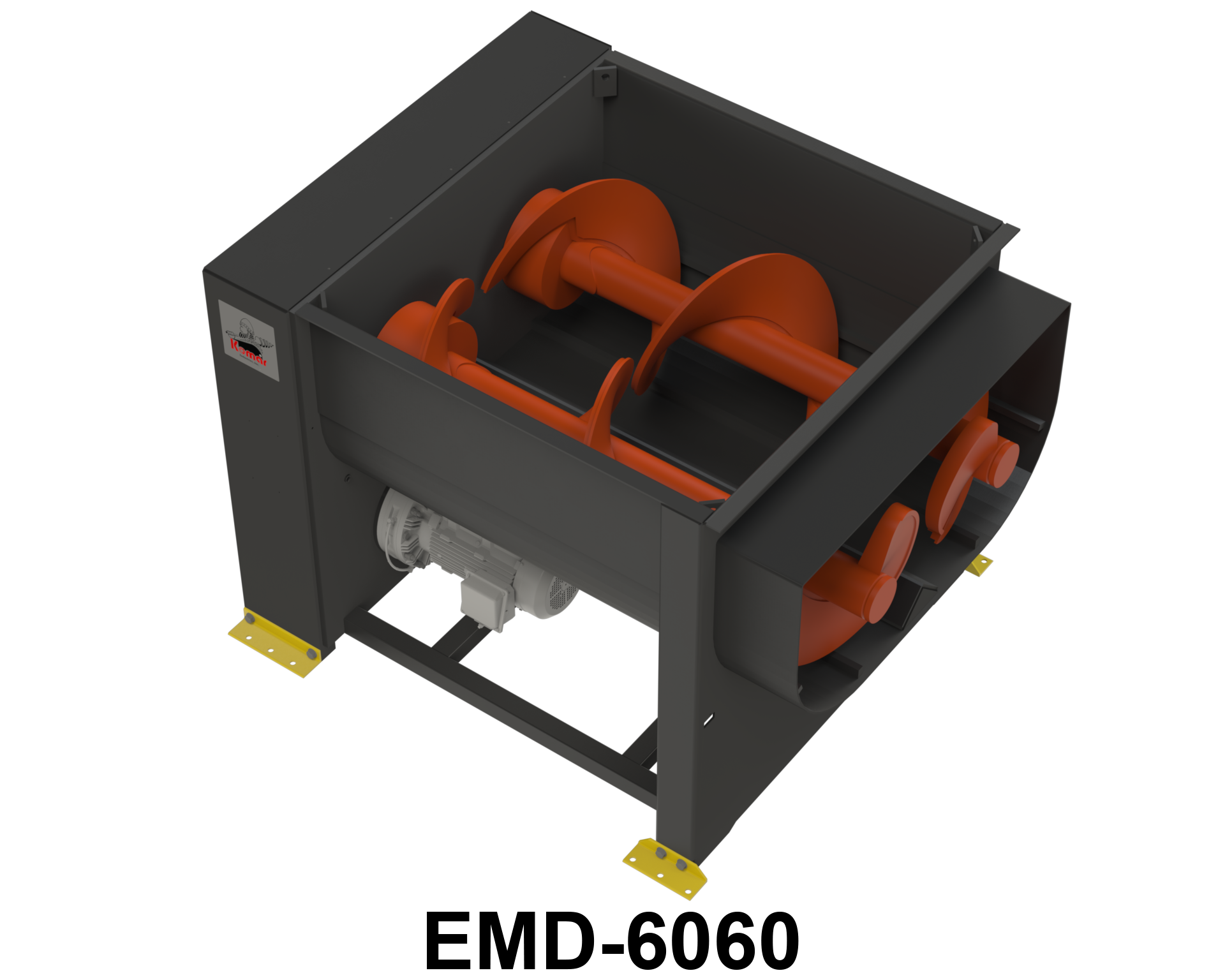

EMD-6060

| EMD-6060 Processing Specifications | |

| Horsepower Auger 1 | 60 |

| Horsepower Auger 2 | 60 |

| Tons / hr | Up to 20 depending on material density |

| Largest Pallet | 72” x 60” |

| Largest Crate | 72” x 60” x 60” |

| Largest Spool | 60” x 72” |

| Feed type | Metered, Forklift, Conveyer |

| Receiving container | 40-50 cu. yd OR compaction trailer |

| Tons per compaction trailer | 16 to 22 tons |

| EMD-6060 Physical Specifications | |

| Footprint (L x W x H) | 150-5/8” x 142” x 66-1/16” |

| Chamber Size (L x W) | 80” x 80” |

| Weight (lbs)** | 32,570 |

| Rpm / Torque ( ft-lbs) Auger 1 | 16.3 / 19,332 |

| Rpm / Torque ( ft-lbs) Auger 2 | 16.3 / 19,332 |

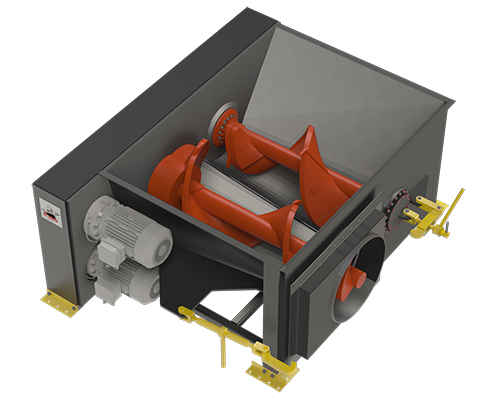

Series Technology

Compaction Auger

Compaction Auger

Breaks down and compacts waste directly into an attached receiving container.

Process Auger

Process Auger

Independently controlled counter rotating screw offers powerful grinding for processing large bulky waste

Patented Solid Lube Bearing Support Systems

Patented Solid Lube Bearing Support Systems

Allows for the use of the biggest and most powerful auger screws in the industry, resulting in maximum compaction force.

Cast Steel Flights

Cast Steel Flights  Tapered Solid Alloy Steel Shaft

Tapered Solid Alloy Steel Shaft

Using the highest quality components to construct our auger screws provides extended service life. The density and shape of the cast flights increases strength and durability, as well as more efficient material delivery to the receiving container. The patented, tapered shaft uniquely distributes the compaction force, maximizing bearing and shaft life.

Auger Teeth

Auger Teeth

All of our wood machines include auger teeth to help with the initial breakdown of dense material.

Cycloidal Drives with 500% Shock Load

Cycloidal Drives with 500% Shock Load

Don’t judge a drive strictly by the motor’s horsepower, especially when you plan to process heavy industrial materials. A high shock load rating is vital in giving the compactor the ability to crunch through large loads.

Worry-Free Chain and Bearing Lubrication Systems

Worry-Free Chain and Bearing Lubrication Systems

The engineered, automatically lubricated chain, coupled with the self-lubricating bearing system cuts down on routine maintenance.

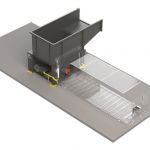

Ratchet Binders

Ratchet Binders  Container Adapter

Container Adapter

The auger compacts directly into a standard receiving container provided by your local hauler, and

meets ANSI and OSHA specifications.