Komar Strengthens Its North American Platform With the Acquisition of Metro Compactor Service

Learn More →Komar Strengthens Its North American Platform With the Acquisition of Metro Compactor Service

Learn More →In a world of evolving regulations, shifting markets, and complex material streams, clarity matters. Komar Industries draws on decades of proven expertise to deliver dependable, purpose-built solutions. What began with pioneering auger technology and shredding innovations has grown into a robust portfolio of durable equipment engineered for precision, reliability, and long-term performance.

We united respected manufacturing brands including Komar Industries, BACE Baler and Compactor, PTR Baler and Compactor, Maren Engineering, and NexGen Municipal along with strategic acquisitions of regional service and installation providers such as Zampogna Inc., A&L Compaction, and Winter Equipment. Together, we bring generations of knowledge under one guiding vision: elevating safety, sustainability, and operational excellence with the steady insight only time can provide.

We engineer smarter systems that transform refuse into value — maximizing performance, reducing risk, and redefining what’s possible in waste and recycling management.

To be the most trusted authority in industrial recycling and waste processing — relied on for our sustainable solutions, technical rigor, unmatched reliability, and forward-thinking innovation.

We do what’s right—always, and especially when it’s difficult.

We design for durability, knowing the strongest equipment endures beyond trends and time.

We show up, follow through, and keep our promises—engineering confidence in every result.

We trust in the expertise of our team, whose dedication, insight, and craftsmanship drive our success.

We innovate for sustainable outcomes—smarter, safer, and cleaner pathways for the future of

waste management.

Komar Industries combines decades of expertise and a diverse portfolio of waste and recycling equipment brands into one powerful platform.

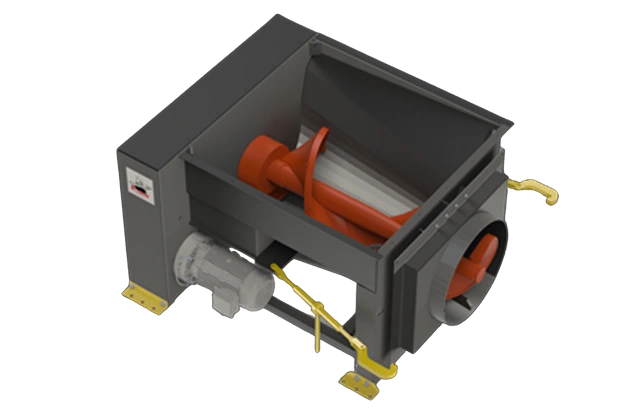

Komar Industries was founded in 1977 on a simple principle: true innovation means reliability. From pioneering auger compactors to today’s advanced processing systems, Komar has spent decades refining waste and recycling equipment through engineering discipline and real-world experience. This commitment to durability and performance has made Komar a trusted leader in industrial waste and recycling equipment.

Komar designs and manufactures auger compactors, industrial solutions, and integrated processing systems that deliver:

With Komar, waste management becomes a predictable, optimized process, reducing logistical burdens and improving operational efficiency.

Founded in 2006 in Charlotte, North Carolina, BACE introduced a data-driven approach to waste and recycling equipment by integrating telemetry and analytics into traditionally mechanical platforms. The brand became known for intuitive technology and a customer-focused service model, reflecting a commitment to transparency, uptime, and the thoughtful application of data to improve everyday workflows.

BACE manufactured vertical balers, stationary and self-contained compactors, and advanced monitoring systems that delivered actionable insights to operators. With built-in telemetry and diagnostic intelligence, BACE equipment helped organizations optimize material value, reduce downtime, and manage recycling processes with clarity and confidence.

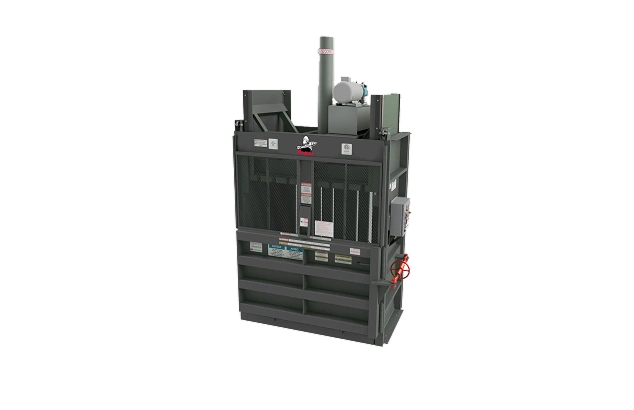

Founded in 1907 as the Philadelphia Tramrail Company, PTR began as a manufacturer of monorails and meat track systems before shifting in the late 1960s to waste and recycling equipment with its first baler. For more than a century, PTR built a reputation for craftsmanship, safety, and reliability—becoming one of the most trusted names in commercial waste and recycling equipment.

PTR manufactured vertical balers, stationary, self-contained, pre-crusher, and vertical compactors engineered for heavy-duty use in demanding retail, warehousing, logistics, and other environments. Known for rugged construction and user-safe controls, PTR equipment was designed to withstand demanding daily cycles while delivering consistent performance and long service life.

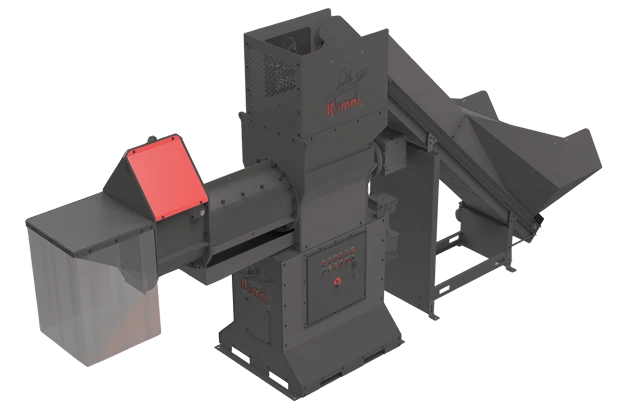

Founded in 1962 in South Holland, Illinois, Maren Engineering established itself as a technical authority in high-volume recycling and waste handling. From early innovations in horizontal baler design to advanced shredding systems, Maren set industry standards for efficiency and reliability—streamlining material recovery and optimizing recycling operations for more than six decades.

Maren manufactured a full line of waste and recycling equipment, including horizontal auto-tie balers, two-ram balers, manual-tie balers, and specialty shredders (pinch conveyor, top-feed, floor-sweep). These systems were designed for high throughput, precision, and durability across diverse material streams and complex operational settings.

Founded in 2014 and headquartered in Burlington, Ontario, NexGen Municipal was established to deliver advanced solutions for municipal and industrial waste and recycling operations. Focused on reducing lifecycle costs and improving sustainability, NexGen became a trusted provider of specialized equipment and systems across North America. Its waste systems were engineered in close collaboration with Komar Industries, leveraging Komar’s expertise in design and manufacturing.

Today, NexGen continues to offer a broad range of solutions, including waste, recycling, and organics collection vehicles; transfer and transport systems; compaction trailers; public area containerization; and integrated processing systems. Additional capabilities include organic extraction for fuel production, waste-to-energy feed systems, airport stormwater management, and industrial shredding and dewatering solutions. All are designed for efficiency, safety, and long-term reliability.

NexGen remains an active brand within the Komar platform.

Founded in the early 1980s, Winter Equipment built its reputation as one of the Midwest’s most dependable regional service providers for waste and recycling machinery. Starting as a small, technician-led operation supporting balers and compactors in industrial and retail environments, the company steadily expanded its capabilities across Ohio and neighboring states. Known for fast response times, deep mechanical expertise, and long-standing customer relationships, Winter became a trusted partner for facility managers who required reliable, same-day support. Its decades of hands-on field experience made Winter a natural fit within Komar Service, adding technical veteran leadership and a strong regional presence to the national platform.

Winter Equipment specialized in the repair, preventive maintenance, and installation of balers, compactors, and scrap-handling systems across commercial and manufacturing facilities. With a strong emphasis on uptime and practical field solutions, Winter’s technicians were known for diagnosing complex mechanical issues, extending equipment life, and supporting high-volume operations with consistent, dependable service.

Zampogna, established in the late 1970s, began as a family-owned service provider supporting waste compactors, balers, and hydraulic systems throughout Pennsylvania, Ohio, and the surrounding Mid-Atlantic region. Over more than four decades, the company developed a reputation for craftsmanship, honesty, and responsiveness, especially within dense metropolitan markets where quick turnaround and safety expertise were essential. Zampogna’s deep knowledge of legacy equipment, diverse OEM platforms, and specialty hydraulic repairs made it one of the region’s go-to service teams. Its integration into Komar Service brought seasoned technicians, regional depth, and a strong culture of customer care into the national network.

Zampogna offered comprehensive field service for compactors, balers, industrial processing equipment, and custom hydraulic systems. Their technicians were known for advanced troubleshooting, heavy-duty component rebuilds, and rapid repair services. Zampogna also supported installation, electrical integration, and ongoing preventive maintenance programs across multi-site retail, industrial, and municipal accounts.

Founded in the mid-1990s, A&L Compaction grew from a small compactor-repair shop into a respected regional service specialist serving Ohio and Michigan. With a strong customer base in distribution, logistics, retail, and food processing, A&L became known for its 24/7 availability and its ability to keep high-demand equipment performing reliably under continuous use. The company excelled in both heavy-duty field repairs and rebuilding aging systems to extend lifecycle value. Its integration into Komar Service added a regional division with decades of practical know-how and a team deeply experienced across nearly every major waste equipment platform.

A&L Compaction provided installation, emergency repair, and routine maintenance for self-contained compactors, stationary compactors, balers, and specialty waste-handling systems. Their capabilities included hydraulic diagnostics, ram and cylinder rebuilds, electrical troubleshooting, and full refurbishment services. These services supported high-throughput environments that demanded reliable, round-the-clock performance.

Together, these brands form a single Komar platform, uniting generations of engineering insight, proven craftsmanship, and data-driven innovation. This integration creates one of the most comprehensive portfolios in the waste and recycling industry, combining augers, compactors, balers, municipal-grade systems, and more under one trusted name.

The capabilities pioneered by BACE, PTR, Maren, and the others now live on. They thrive within Komar’s unified approach, delivering smarter, safer, and more reliable solutions with the steadiness that only time, expertise, and purpose can provide.

With more than 40 years of experience in the waste processing industry, Mark joined the company in 1986 and has played a pivotal role in its growth ever since. His early career was marked by hands-on involvement across all aspects of the business, followed by extensive global work designing and building large-scale waste processing systems for industrial, municipal, hazardous, and radioactive waste streams.

Chris Lauletta joined Komar in 2025 to lead all Commercial functions—including Sales, Marketing, and all Aftermarket teams. With more than 30 years of global commercial leadership across industrial services, manufacturing, and international markets, he brings deep expertise in driving growth through market expansion, aftermarket strategy, cross-selling, and strategic customer relationship management. Throughout his career, Chris has built a proven track record of delivering double-digit top and bottom-line results, leading complex business transformations, and elevating commercial excellence across large, geographically dispersed organizations.

Phil Hammond joined Komar in 2021 as Chief Financial Officer, overseeing all Finance and IT functions, including accounting, FP&A, and treasury. He brings more than 28 years of experience leading high-performing teams within multi-billion-dollar, privately owned, and private equity-backed manufacturing companies. Throughout his career, Phil has demonstrated a proven ability to combine deep financial expertise with a strong operational mindset. He is recognized for driving profitability, improving capital efficiency, and guiding organizations through periods of rapid growth and transformation.

Joining Komar in 2023, Ryan leads the organization’s people and culture strategy, overseeing all aspects of human capital management, including talent planning, employee and labor relations, total rewards, HR operations and technology, and organizational and cultural development. With nearly two decades of progressive HR leadership and strong business acumen, Ryan is known for translating business strategy into practical people solutions, guiding organizations through change, and building scalable HR programs that support growth, performance, and long-term organizational success.

John Stafford serves as the Chief Operations Officer at Komar, having joined the company in 2023 to lead Operations across safety, quality, customer fulfillment, manufacturing, engineering, procurement, and continuous improvement.

John came to Komar with 38 years of successful operations leadership in both automotive and industrial businesses. His experience spans across successive levels of management from supervising operations on the factory floor, automation manager, new vehicle launch manager, department manager, plant manager, global operations director, and global operations vice president.

Tim Backs joined Komar in January 2023 to spearhead the company’s strategic growth and corporate development initiatives. With over 25 years of leadership experience across Fortune 500 and private equity-backed environments, Tim has a proven history of scaling businesses from $500M to over $2B in revenue. A seasoned M&A leader, he has overseen more than 50 domestic and international acquisitions with a combined equity value exceeding $1.5B. Throughout his career, Tim has remained focused on strengthening solution offerings, accelerating geographic expansion, and consistently delivering high-impact shareholder value.

More than a century of engineering wisdom, durable design, and service expertise—united under one vision.

Together, these groups form Komar Service, a 24/7 nationwide network built on OEM engineering knowledge, regional specialization, and a shared commitment to reliable, customer-first support.

Built on more than a century of engineering innovation and integrated field experience, Komar delivers one of the industry’s most comprehensive portfolios including augers, compactors, balers, municipal systems, advanced monitoring technologies, and more. This portfolio is supported by a national service platform committed to clarity, durability, and long-term performance.

Komar continues to expand capabilities for the future, transforming waste into value through engineered wisdom and purpose-driven innovation.

Komar Service unites decades of factory-direct expertise from Komar, PTR, and BACE, each operating nationwide with factory-trained technicians and established service programs. Komar has historically handled most installations and service in-house for its equipment, while PTR and BACE, in addition to their in-house support, maintain extensive national networks with 24/7 support. Maren contributes additional technical resources, complementing these OEM capabilities.

To expand coverage and responsiveness, Komar integrated leading regional specialists: Winter Equipment Corp., Zampogna Inc., and A&L Compaction. Together, these teams form a single platform with deep OEM expertise and strategic regional divisions.

24/7 Nationwide Support for Komar family equipment and all major OEM machines.

Installation & Preventive Maintenance programs led by factory-trained technicians.

Emergency Repair when every minute counts.

Lifecycle Optimization for balers, compactors, shredders, auger systems, and integrated recycling lines.

Aftermarket Parts & Components We provide genuine and universal parts for all brands ensuring repairs and rebuilds meet the highest standards of reliability and performance.

Komar Service provides a single point of accountability, combining OEM depth with regional reach so customers can count on clarity, dependability, and expertise everywhere.

We are a waste solutions company. With a wide array of application-specific models and advanced engineering capabilities, we look forward to guiding you to the best solution for the job.

Schedule a free waste stream evaluation to identify the right equipment and processes for your space, waste types, and volume.