Continuous Waste Feed Systems

The Komar continuous waste feed systems offer the unique ability to provide a metered feed while eliminating air transfer thru the feeder. Developed for feeding incinerators, and proven for more than 30 years in difficult applications such as hazardous and radioactive waste, our feeders utilize extruded material to generate an air seal and provide unmatched feed control.

TYPES

-

Multistage Processing Systems

Shred-Feed, Palletized Hazardous Waste, and Baled MSW/RDF

-

Stand-Alone Feeders

Electromechanical and Hydraulic base units

-

Auxiliary Equipment

Multi-Stage Processing Systems

Shred-Feed

- Drive Type:

- Electromechanical and Hydraulic

- Application:

- Incineration and Gasification

- Volume:

- Medium-High (500-50,000 lbs/hr )

- Turn Down Ratio:

- 10:1

- Feed Stock:

- A shredder is added to a hydraulic feeder when material is either too large to initially fit into the feeder’s processing chamber, or when a consistent piece size is needed for a more successful feed.

Palletized Hazardous Waste

- Drive Types:

- Hydrostatic

- Applications:

- Incineration and Gasification

- Volume:

- High (10,000-50,000 lbs/hr)

- Turn Down Ratio:

- 10:1

- Feed Stock:C

- Containerized hazardous solids, liquids, or resins that need to be thoroughly blended before feeding to obtain a higher level of consistency. Systems can handle up to four drums or one cubic yard per charge.

- Drive Type:

- Hydraulic

- Application:

- Incineration and Gasification

- Volume:

- Medium-High (10,000-50,000 lbs/hr )

- Turn Down Ratio:

- 10:1

- Feed-Stock:

- Baled MSW / RDF

- System Components:

In-Feed Conveyor

In-Feed Conveyor  Material Lift

Material Lift  Airlock

Airlock Hopper w/Ram In-Feed Assist

Hopper w/Ram In-Feed Assist  Shredder

Shredder  Feeder

Feeder

Water Cooled Extrusion Tube

Water Cooled Extrusion Tube  Rotary Isolation Gate

Rotary Isolation Gate Gasifier (Komar does not supply the gasifier)

Gasifier (Komar does not supply the gasifier)

Stand-Alone Feeders

ELECTROMECHANICAL

- Drive Type:

- Electromechanical

- Application:

- Pilot Scale or Small Incineration and Gasification

- Volume:

- Low-Medium (200-1000 lbs/hr)

- Turn Down Ratio:

- 2:1 (or 50% of full displacement)

- Feed Stock:

- Consistent and Compressable

*Designs can vary based on material and application.

| Model | Motor Type | Tube Inner Diameter | Horsepower |

| EF-6-10 | Electromechanical | 6″ | 10 |

| EF-8-10 | Electromechanical | 8″ | 10 |

| EF-12-20 | Electromechanical | 12″ | 20 |

| EF-18-20 | Electromechanical | 18″ | 20 |

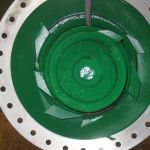

HYDRAULIC

- Drive Type:

- Hydraulic

- Application:

- Incineration and Gasification

- Volume:

- Medium (200-12000 lbs/hr)

- Turn Down Ratio:

- 10:1 (or 10% of full displacement)

- Feed Stock:

- Can handle a wider variety of material types and volumes than electromechanical feeders, while still maintaining the selected feed rate.

- Injector:

- Added when batch material input needs to be metered through a small diameter output, achieving a very high level of feed control.

*Designs can vary based on material and application.

| Model | Motor Type | Tube Inner Diameter | Horsepower |

| HF-12-40 | Hydraulic | 12″ | 40 |

| HF-18-75 | Hydraulic | 18″ | 75 |

| HF-20-100 | Hydraulic | 20″ | 100 |

| HF-24-100 | Hydraulic | 24″ | 100 |

| HF-36-200 | Hydraulic | 36″ | 200 |

| HF-42-400 | Hydraulic | 42″ | 400 |

Auxiliary Equipment

Staging Conveyors

For automated indexing and metering of containerized materials into the feed system.

Material Lifts

For automated lifting of materials into the feed system.

Infeed Airlocks and Slide Gates

Sealed environments for nitrogen purging.

Explosion Venting, Isolation Gates, Water Cooled Tubing

Protects equipment in volatile and high heat environments.

O2 Monitoring, Nitrogen Purging, CO2 Suppression

For controlling gases within the feed system.

Service Platforms, Service Trolley

For ease of access during system maintenance.

Sizing Shredders

For primary reduction of materials prior to feeding.

In-Feed Conveyor

In-Feed Conveyor  Material Lift

Material Lift  Airlock

Airlock Hopper w/Ram In-Feed Assist

Hopper w/Ram In-Feed Assist  Shredder

Shredder  Feeder

Feeder

Water Cooled Extrusion Tube

Water Cooled Extrusion Tube  Rotary Isolation Gate

Rotary Isolation Gate Gasifier (Komar does not supply the gasifier)

Gasifier (Komar does not supply the gasifier)